Sealed central heating systems and open vented heating systems

Open or closed central heating systems?

It’s common that older heating systems will most likely home an open vent boiler with a feed and expansion tank. When refurbishing a plant room should you retain this or opt for a sealed system?

We take a look at the key differences between open vented systems and sealed systems to help you decide what is best for your commercial heating refurbishment project. If you need more advice or want someone to look at your heating system request a free site survey from our team of sales engineers who can advise on the best solution.

What is an open vented system?

A heating system which is open to the atmosphere and has a feed and expansion tank.

How does an open vented heating system work?

To accommodate water losses from evaporation or leakage in the system the tank water level is maintained and topped up automatically using a float valve in the tank connected to the mains supply. Expanded water is also accommodated within the open expansion tank. The system pressure or head is achieved through the height of the tank location above the plant room.

Feed and expansion tanks are typically installed in roof voids and the height of the tank above the boilers must satisfy minimum operating pressure for the installed boiler and have sufficient height above the highest point of the circulating system to satisfy the requirements of former Health and Safety Executive Guidance Note PM5 (Please note: Hamworthy still advise to satisfy this standard despite PM5 no longer existing).

What are the downsides of an open vented system for modern boilers?

An open vented system is typically used in older heating systems and cannot get to high pressures. It can allow pollutants to enter the system water. Feed and expansion tanks will require periodic cleaning and enable oxygen to enter the system that can contribute to corrosion. The pipe work run from the tank location to the plant room can sometimes be arduous and will need insulating to protect against freezing.

Open vented heating system schematic

What is a sealed system?

A heating system that is closed to the atmosphere and does not have a feed and expansion tank.

How does a sealed system work?

Sealed systems will use a pressurisation unit to provide automatic replacement of water losses and ensure minimum head requirements are maintained. A dedicated expansion vessel will also need to be installed to deal with the effects of heating fluid expansion and contraction that will occur as the heating fluid temperature changes across the entire operating temperature range of the sealed heating system.

Both units need to be accurately sized for the system it is being used on (please see Hamworthy brochure for information on pressurisation unit sizing and expansion vessel sizing).

What are the benefits of a sealed system?

At Hamworthy we recommend the use of a sealed system. Sealed systems take up less space, assist with system cleanliness, improve water quality and reduce oxygen ingress.

Sealed systems have the benefit of all equipment - pressurisation units and expansion vessels - being located in the boiler room, making service and maintenance access simpler.

Pressurisation units offer the additional benefit of monitoring system pressure, so that appliances can be interlocked to prevent operation in the event of operating pressure conditions being too high or too low.

Some pressurisation units monitor water volumes introduced to the system which can help identify leaks as well as helping decide when corrosion inhibitors may need re-dosing.

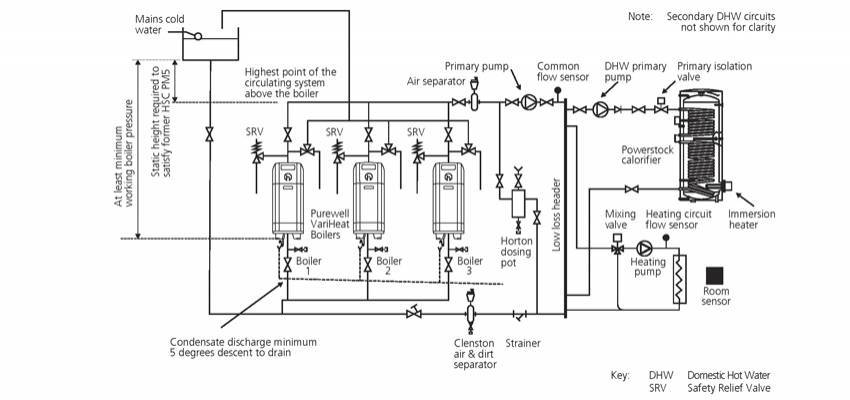

Sealed heating system schematic

What is best for your commercial heating system?

This will depend on many factors including the age and state of the existing heating circuit, location and space in the plant room, as well as the type of boiler you are installing.

Many manufacturers are now stipulating a sealed system to ensure system cleanliness and protect the boilers. Hamworthy’s Upton condensing boilers and Stratton mk2 wall hung boilers are suitable for installation in sealed heating systems only. However, our Purewell Variheat cast iron condensing boiler can be installed in an open heating system.

For more advice call our technical team or request a site visit to review your current commercial heating system.