What is a low loss header?

Maintaining the flow – what is the role of a low loss header in commercial heating systems?

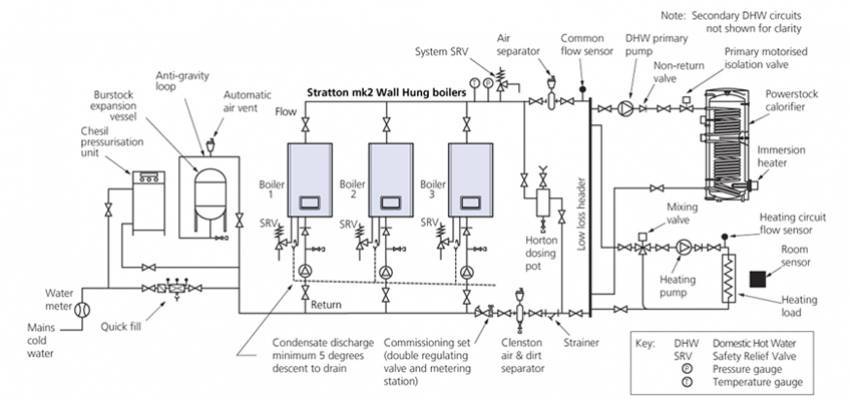

Low loss headers, also referred to as common headers, have been used as best practice heating system design for many years now. We take a look at the role they play and what to consider when installing them.

Why do I need a low loss header?

Heating systems where boilers are connected directly to the loads may have a variable flow rate caused by system control valves and Thermostatic Radiator Control Valves (TRVs). This can lead to minimum boiler flow rates not being maintained.

Hydraulic separation of primary and separately pumped secondary circuit via a low loss header is recommended to avoid this.

How does a low loss header work?

By separating the two systems it allows boilers to operate at a constant flow rate in the primary circuit whilst flow rates and temperatures may vary in the secondary circuit. This avoids any interaction between the two and enables the primary circuit return temperature to represent the load on the system. It also permits return temperature sequence control of multiple burners.

What are the benefits of a low loss header?

By regulating the flow rate and pressure, efficiency and performance of the heating system are improved. Boilers are safeguarded from irregular flows, ultimately increasing the life of the boiler.

If installed vertically, low loss headers can help collect sludge from the system. Due to the low flow velocity through the low loss header, the debris from the system has time to fall to the bottom of the header and traps for safe removal via a drain valve.

However, we would still advise having a dedicated air and dirt separator installed on the system or the use of a low loss header that has integrated air and dirt separation (our Upton boiler is the first product to feature an optional low loss header with a combined air and dirt separator).

Low loss header sizing – what do you need to know?

The size of the low loss header relates to the output of the boiler and the system load, design and chosen temperature differential.

The header should be sized so that the pressure loss at full flow is small. All secondary circuit flows and the flow from the boilers should normally be at the top, or one end of the header. All secondary circuit returns and the return to the boilers should be at the bottom, or other end of the header. This helps ensure correct entry temperature into the secondary circuits by avoiding temperature dilution of the flow temperature along the low loss header.

It is important that the volume of water circulating through the boiler loop is correct for the installed boiler output and design differential temperature. This ensures good boiler control, especially when using high efficiency, low water content boilers.

We can provide sizing guidance for low loss headers as well as corresponding low loss headers specifically designed to match the performance of our boilers, the Stratton mk2 wall hung boiler and our new Upton floor standing boiler.

What else do I need to consider when installing a low loss header?

Pumps

- Pump yes or no: ‘Does the boiler have an integral pump?’

If not, additional pumps will be needed. Their size will be relative to the resistance and flow rate of the boiler(s).

- Location and type of pumps: single boiler shunt pumps or single primary circuit pump?

There are pros and cons to each and it will depend on your installation, system design, control philosophy and budget.

System

- What’s installed on the secondary circuit – Mixed temperature heat emitters such as underfloor heating (low temperature) and radiators (high temperature)?

How many boilers are installed on the primary circuit?

- What are the manufacturers stated minimum flow rates for the installed boilers? (always refer to the technical manuals)

- What are the temperature differentials on the circuits?

This has changed over time due to market-driven applications such as district heating and underfloor heating and the use of plate heat exchangers requiring larger temperature differentials.

Building

There are lots of options to consider when designing your commercial heating system which will be dependent on your building, project and system requirements. You can get guidance on low loss headers from your local Hamworthy expert or our in-house technical team.

Any questions? Interested in a low loss header?

Speak to your local sales managers to discuss your low loss header requirements. Get in touch with our friendly team.