Refurb or replace – what to consider when upgrading your commercial heating system

Whether it be through budget or time constraints, many of our customers don’t have the capacity to carry out a full replacement of their commercial heating systems. There may be plans to bring in a sustainable heat pump solution in the future, or the building use may be changing significantly in the long term, so a cost-effective, low risk refurbishment of the existing system may be the best approach to improve compliance and efficiency in the meantime.

When you are refurbishing or repairing your current plant room there are some standard steps that you will need to go through to ensure an optimum approach.

Assess and take stock

Firstly, consider your current system. You will either have a closed system or an open vented system and this will determine the amount of work required and the products you will need.

It’s quite common for older plant rooms to be open vented, which will have some downsides – including risk of pollutants and lack of pressure - and can limit your longer-term choices. If this is the case you will need to decide if you want to retain this open system, and work around it, or replace it with a sealed system. It’s worth noting that many of our boilers must be installed in a sealed system to ensure system cleanliness and protect the boilers.

If you already have, or have chosen to install, a sealed system you will have more flexibility for the future and can save time and space as well as improving monitoring in the long term. Sealed systems are closed heating systems, that do not have a feed or an expansion tank. Instead, they use a pressurisation unit to automatically replenish water lost and maintain required minimum head levels. They also need a dedicated expansion vessel to manage the impact of expanding and contracting heating fluid.

Size your need

Sizing a hot water or heating system for a commercial premise is less about the size of the property and more about projected peak demand and patterns of peak usage. You need to therefore consider how the building is going to be used both in the short and longer term. It may be that the building use has changed, and demand has risen, or that any replacement equipment doesn’t need to be as big and can be resized to reduce energy or wastage. The boiler may even have spare capacity for you to install a calorifier – which is cheaper and simpler to install than a direct fired water heater – or you may require new equipment to comply with regulations and reduce energy.

You can see here a recent case study at an office block in London that chose a calorifier to be heated by the existing boiler to replace a failed water heater and overcome flue issues on site.

Consider your existing flue

The type of flue you have could determine what direction you take your refurbishment.

The Energy Related Products (ErP) Directive has effectively eliminated most high efficiency non-condensing boilers up to 400kW and you may need to change from an atmospheric boiler to a condensing boiler. This could mean that you’ll also require a replacement flue or for the flue to be lined to cope with the condensate.

It’s a similar case for water heaters. The ErP regulation came in later than it did for boilers, but - from September 2017, stricter energy efficiency limits were introduced. This has meant a shift from atmospheric water heaters to condensing water heaters. However, due to advancements in product design, we’re are able to offer an atmospheric water heater that is both low NOx and able to meet the energy efficiency criteria of the directive. This makes replacement much simpler and quicker, and time is often an important factor when you need to change a failed water heater to enable your building to operate.

Define your key components

Boiler

Your boiler is often at the heart of your heating system and likely to be the main component of your refurbishment. When selecting a boiler, you will need to consider the job that it needs to do – particularly the demand for heating – as well as the fuel type. You will also need to consider the amount of space and time you have available for the project.

We have many commercial boilers and water heaters that are suited to refurbishments of existing systems.

The Purewell Variheat mk2 boiler is a cast iron boiler with large waterways that is more tolerant to older systems. It has a similar footprint and centres to older atmospheric boilers, so it swaps out well. It’s one of our only boilers that it is suitable for both sealed and open vented heating systems and may not even need system separation. It is simple to run and maintain which saves time, money and reduces risk.

The Varmax boiler needs less supporting equipment. It’s an easy to install condensing boiler with no need for a dedicated primary circuit with associated pumps, controls and low loss header. It fits existing systems with no minimum flow required, meaning it doesn’t depend on the secondary circuit flow for safe

operation.

Finally, the Dorchester DR-LL water heater is an ErP compliant, low NOx atmospheric water heater that keeps costs to a minimum for systems that still have atmospheric flues. This easy-to-maintain water heater minimises flue changes1 on replacement projects and can still meet the needs of premises with large demand for hot water.

1Subject to survey. New draught diverter must be fitted

Hydraulic Separation

There are two sides to any heating system and it’s important to consider that when you are looking to make replacements and refurbish rather than a complete overhaul. Ideally your primary circuit – containing your boiler – should be sealed, but your secondary heating system circuit – including your radiators, etc – can remain open provided you separate the circuits with an appropriate hydraulic separation system.

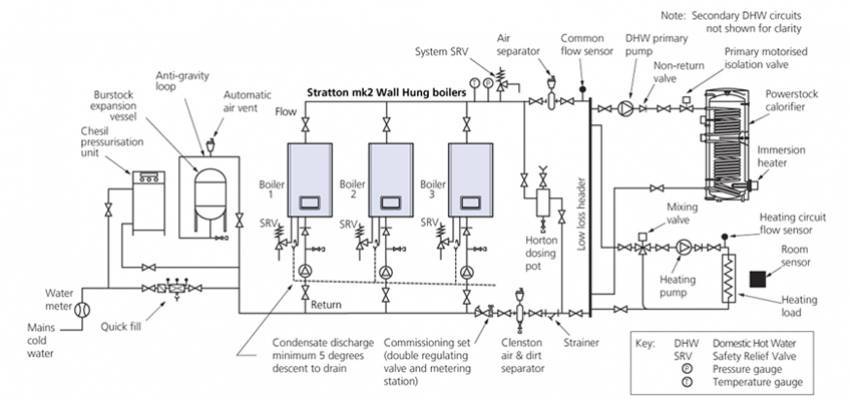

A hydraulic separation system – such as a plate heat exchanger or low loss header - will ensure flow, resistance and temperature can be maintained around the primary circuit, as well as guarding against the transference of sludge, dirt and even air from the secondary, open system, protecting your investment in new boilers.

Plate heat exchangers do not mix the water between the two circuits at all and therefore provide greater separation. There are a number of types available, and selection will depend on whether you want a fixed unit (brazed plate) or plan to extend the heating circuit in future (gasketed type).

Low loss headers still connect water flows between the two circuits but ensure adequate flow, resistance and temperature around the primary circuit that the boilers are installed in. A vertical low loss header with a low flow velocity allows sludge to be separated and removed from the system through regular maintenance. A low loss header is often supplied as a package with a new boiler and will be correctly sized to suit that boiler’s connections.

Identifying the appropriate hydraulic separation system - or a boiler that doesn’t need separation - will allow you to replace your open vented boiler with a sealed system including a modern condensing boiler and keep it protected from corrosion, dirt and air, as well as allowing you to maintain efficient pressure and flow rate through the boiler.

Support

Whatever the scope of your system overhaul, you can get expert support at any time from Hamworthy. We’re happy to help you with anything from sizing your system requirements, and identifying the most cost effective approach to upgrading your system, and from product selection to long term spare parts availability.

If you need more advice or want someone to look at your heating system request a free site survey from our team of sales engineers who can advise on the best solution.

Alternatively, Email us or visit our technical library